Our Patent Families

We proudly hold 29 registered patents, each marking a significant leap in technological innovation. These patents span diverse areas, showcasing our commitment to advancing imaging techniques, AI algorithms, hardware solutions, and software frameworks. They reflect our drive for excellence and secure our competitive edge while propelling the industry forward. With this extensive patent portfolio, we lead in driving transformative change and setting new standards in innovation.

Nanox.SOURCE

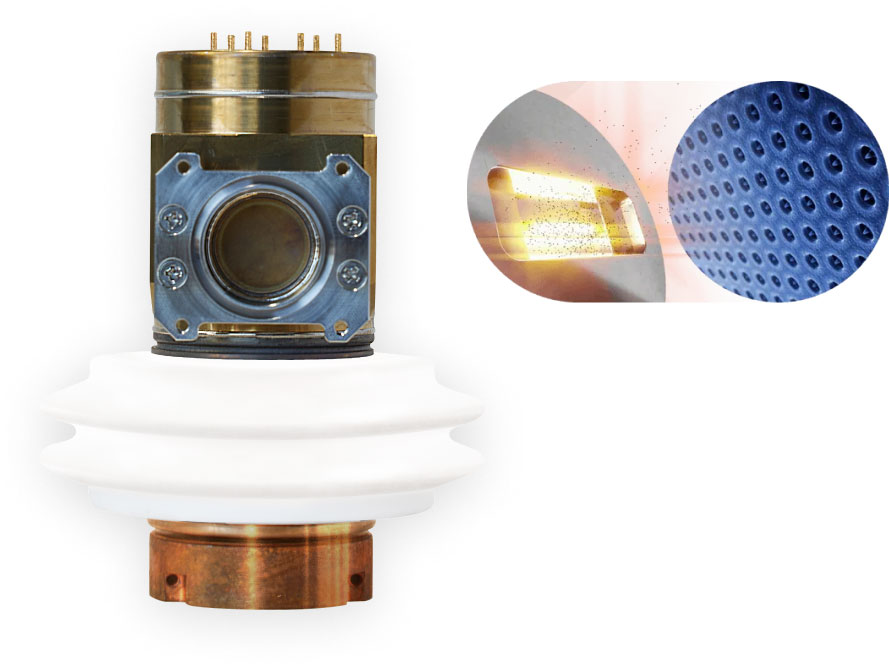

Nanox.SOURCE

A proprietary silicon-based, low voltage, nano-scale cold cathode generating the electron stream needed for X-ray via field-emission technology

Read More about Nanox.SOURCEFDA

510(k) cleared imaging systems using the Nanox.SOURCE

10

Patent families, registrated in various countries

9

Years developing the source for the medical imaging industry

FED TECHNOLOGY

Over a decade of substantial resources invested in development of FED technology by Sony

Nanox.TUBE

Nanox.TUBE

From a single metal filament heated to 2,000° Celsius, requiring special cooling and rotation mechanics, to a silicon chip featuring a field of 100 million nano-cones emitting digitally controlled electron streams under low voltage.

Read More about Nanox.TUBEFuture Benefits of Cold Cathode X-ray Tubes

Size Improvements

Most beneficial in mobile imaging units that run off chargeable batteries.

No filament heating is required to “boil off” electrons from the cathode.

Energy Efficiency

Cold Cathode tubes are much smaller and lighter then conventional X-ray tubes.

Drastically reduces the size and complexity of imaging systems, and consequently, their cost.

Multi-source Imaging

Allows simultaneous connection and switching of multiple X-ray tubes.

Only two voltages control X-ray output: the Cathode-Anode voltage and the Cathode Cone-Gate voltage.

Nanox.CLOUD

Nanox.CLOUD

A proprietary software platform designed to streamline the radiology diagnostics services, image processing and Nanox.ARC fleet management.

Read More about Nanox.CLOUDNanox.CLOUD Enables

Cloud based image reconstruction

No need for costly hardware

Continuous updates

Centralized protocol management

Provide and maintain scan protocols to the Nanox.ARC devices.

Remote installation capability

24/7 remote support

HIPAA & GDPR compliance

Nanox.AI

Nanox.AI

Nanox AI’s solutions are developed to target highly prevalent chronic and acute diseases affecting large populations around the world. Leveraging AI technology, Nanox AI helps clinicians extract valuable and actionable clinical insights from routine medical imaging that otherwise may go unnoticed, potentially initiating further medical assessment to establish individual preventative care pathways for patients.

Read More about Nanox.AIPioneering Technologies Driving the Future of Innovation

Artificial Intelligence

Nanox.AI develops artificial intelligence algorithms in multi-modality of medical imaging, using state of the art technology

Deep Learning

The technology uses deep learning networks that rely on the Nanox.AI medical imaging data lake

Data

Lake

The Nanox.AI data lake contains millions of anonymized HIPAA-compliant medical images and reports

Proprietary Technology

Proprietary technology uses NLP to process medical reports on a large scale, enabling smarter data curation

Customer Needs

Nanox.AI develops technology aligned with customer needs and requirements

Seamless Workflow

Providing a seamless workflow in the healthcare system with wide and flexible customization and integration capabilities

Cutting-Edge Medical AI Technology

Over a decade of Al imaging experience

Collaborations

Together, We Redefine Possibilities

Client portal

Client portal